Beyond the Catalog

Many industrial rubber components are treated as “standard” commodities, but at RPM, we know that a standard part often leads to premature failure if it isn’t matched to your specific environment. We take common profiles—like bumpers, grommets, and tips—and customize the material, durometer, and geometry to solve your unique challenges.

Whether you are looking for a standard replacement or a better-performing custom alternative, we provide the engineering expertise to ensure the part works exactly as intended.

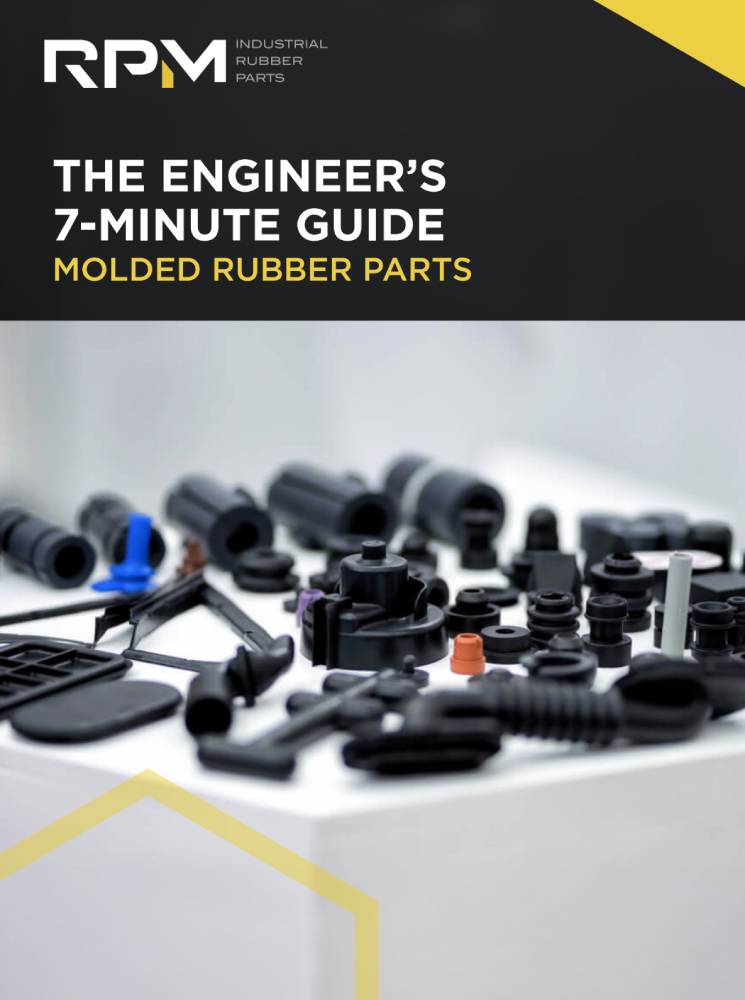

Our Molded Rubber Capabilities

We manufacture a wide range of essential components, each of which can be tailored for specific load requirements, chemical resistance, or environmental exposure.

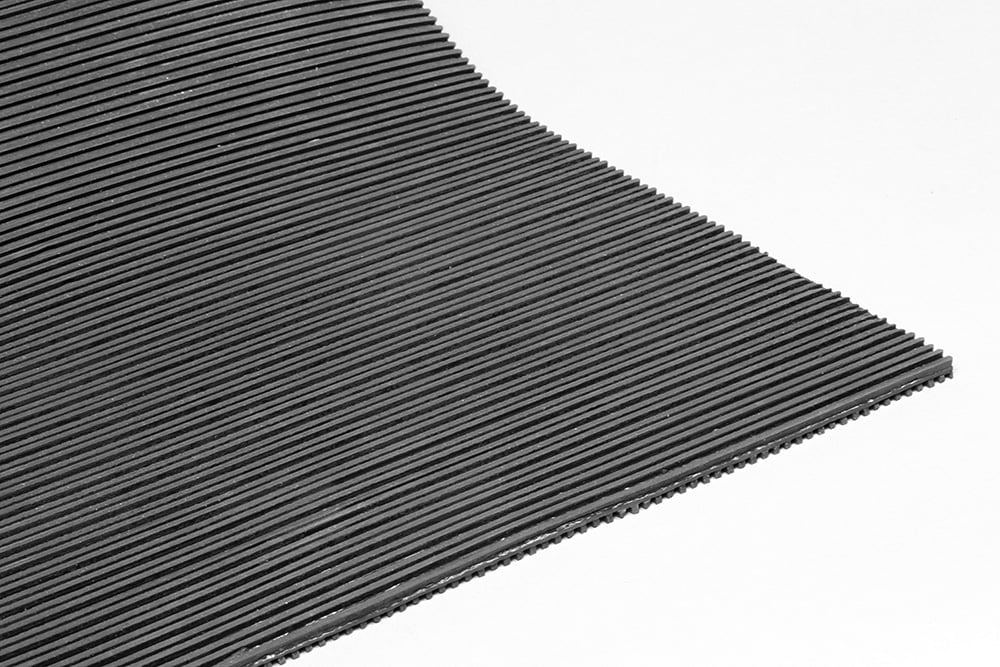

- Bumpers & Anti-Vibration Pads: Engineered to absorb high-impact energy and protect surfaces from mechanical wear.

- Grommets & Flanged Stem Bushings: Durable pass-throughs designed to protect internal components and provide secure alignment.

- Suction Cups & Vacuum Lifters: Custom-compounded for the precise grip and flexibility required for automated material handling.

- Tips & Caps: Protective covers molded to seal out debris or provide a finished, ergonomic end-point for equipment.

- Compressor Mounts: Specialized isolators designed to handle the specific thermal and mechanical cycles of HVAC and industrial systems.

- Self-Adhesive Bumpers: Rapid-install protection for lightweight industrial enclosures and electronic assemblies.

Industries

The Engineer’s 7-minute Guide to Rubber Molded Parts

Our free resource is a quick-reference guide to help you determine if exploring a rubber part is right for your application.

Standard Molded Rubber Parts

Thousands of rubber parts. Find yours.

Grommets

128 Products

Bumpers

70 Products

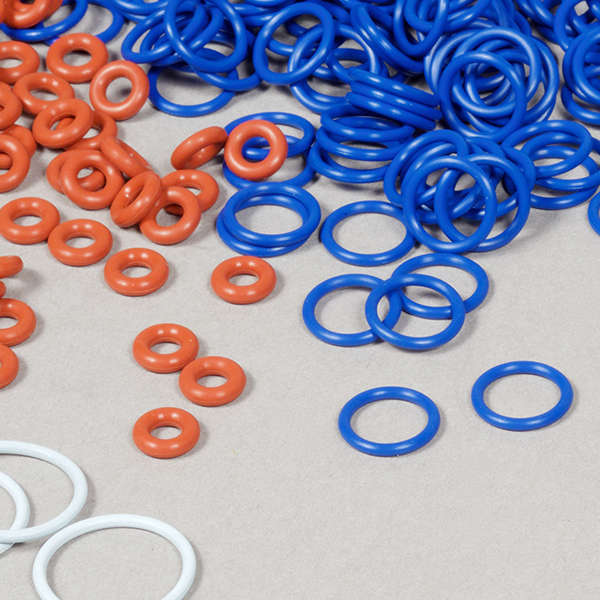

O-Rings

395 Products

Flanged Stem Bushings

16 Products

Compressor Mounts

3 Products

Anti-Vibration Pads

2 Products

Tips And Caps

19 Products

Suction Cups And Vacuum Lifters

49 Products

Self Adhesive Bumpers

126 ProductsThe RPM Advantage: Why Custom is Better

- Move Beyond “Off-the-Shelf” Limitations A standard part might fit the hole, but will it last in your environment? Often, customers come to us looking for a standard catalog part, only to realize that a custom-engineered version provides significantly better performance and longevity for a similar price point.

- Material Selection Built for Your Environment Don’t settle for general-purpose rubber. We help you select the ideal elastomer—whether it’s Nitrile for oil resistance, EPDM for UV exposure, or Silicone for high-heat environments—to ensure a longer lifespan for your machinery.

- In-House Engineering & Tooling You don’t need a final blueprint to get started. If you have a failed part or a new design concept, we handle all tooling and prototype development in-house at our Canadian facility. This allows us to deliver custom solutions with shorter lead times and higher quality control.

- Scalable Production from Prototype to Volume We don’t require massive batch sizes to prove out a design. Our flexibility allows you to test custom parts in real-world conditions and scale up to full production runs once the design is validated.

Let’s Build a Better Part

Have a drawing? A failed part? Or are you just tired of replacing “standard” components that don’t last?

Contact us today. We’ll help you design and mold the right rubber solution so you can focus on what your machines were built to do.

Our Proven Process

Our extensive experience has tested and perfected our process over the last 50 years.

Step 1

Consultation

& Design

We work closely with you at all levels to understand your needs so that we can design and deliver the right part for your unique application.

Step 2

Prototype

& Pre-production

When the design has been confirmed, we fabricate tooling, run some initial prototypes and send to you for validation and/or approval.

Step 3

Production

Once the fit and function has been proven and confirmed, we’re ready to work with you to commence a full production run.

Step 4

Delivery

When the order is complete, our warehouse team package’s and ships the product, ensuring on time delivery. We also offer warehousing services to help you manage your inventory and lead times.

Frequently Asked Questions

Find quick answers to your questions here or contact us directly for any additional inquiries.

What are the benefits of rubber compression molding?

Compression molding offers several advantages, including high production rates, excellent dimensional stability, and the ability to produce complex shapes with intricate details.

Which is better? Natural rubber or synthetic rubber?

Natural and synthetic rubbers each have strengths. Natural rubber is great for flexibility, while synthetic rubbers can be customized for specific needs like heat resistance. The best choice depends on the specific application.

How do I select a vibration isolator for my application?

To select the right vibration isolator, start by determining the frequency and amplitude of the vibrations, the weight of the equipment, and the desired level of isolation. Contact the team at RPM for assistance.

What is rubber-to-metal bonding?

Rubber-to-metal bonding involves creating a strong and durable connection between rubber and a metal surface, resulting in a composite material that combines the flexibility and shock absorption of rubber with the strength and rigidity of metal.

What is an engine mount and how does it work?

An engine mount is a flexible component that isolates the engine from the vehicle’s frame, reducing vibrations and noise while allowing for slight engine movement during operation.

What is a rubber sandwich mount?

A rubber sandwich mount is a vibration isolation device consisting of two metal plates with a layer of rubber sandwiched between them, used to reduce the transmission of vibrations.

Ready to get started?

If you need rubber, we’ll have it. If we don’t have it, we’ll find it. If we can’t find it, we’ll make it.

Or Call Us: 888-842-5668