For vibration isolation and shock reduction, engineers choose sandwich mounts. These mounts provide optimal vibration isolation, have high load carrying capacities, and are easy to install. The options may be overwhelming if you aren’t sure which mount to choose.

From elastomers to static load, there is a lot to think about. At RPM Industrial Rubber Parts, our team is ready to walk you through the options. Give us a call at (888) 842-5668. You can also take a look at our guide on selecting the right vibration isolation mount.

Whether choosing an existing sandwich mount or designing a brand new one, there are a few things to consider first.

Sandwich Mount Materials

Because sandwich mounts are such vital parts of machinery, they are used in many industries. These are some of the industries that commonly use sandwich mouSandwich mounts are made of both rubber elastomers and metal. The metal is typically aluminum, steel or stainless steel. The elastomer, however, could be one of many different kinds. Here are some of the different types of elastomer that are used in sandwich mounts:

- Natural rubber: high strength and efficient vibration damping, but have a small temperature range.

- Neoprene: excellent tensile strength and vibration damping, but also has a small temperature range.

- Silicone Elastomer: excellent for high-temperature applications, but tends to have poor abrasion and tear resistance.

- SPE I: specially designed by LORD, this polymer has high vibration damping and temperature flexibility.

- Broad Temperature Range: another LORD polymer, this silicone comes in a few variations – BTR, BTR II, and BTR VI. It has a wide range of anti-vibration and shock capabilities and temperature resistance. Excellent for mission-critical applications such as Military and Aerospace.

Depending on the elastomer of the sandwich mount, the final part will end up with specific capabilities.

Sandwich Mount Environmental Resistance

This is one of the most important capabilities of a sandwich mount. These parts are extremely versatile and that means they are used in a variety of applications. They need to perform in heat, sunlight, and highly toxic environments. Sandwich mounts are incredibly versatile and are used in military, agricultural, construction, mining, oil, and gas environments. The sandwich mount should be able to withstand temperatures below 0º F and above 300º F.

Here are a few other environmental factors to consider:

- Temperature – High and Low

- Fluid (hydraulic, oil, and fuel)

- Ozone

- UV

- Abrasive Environments – Dust, Sand Etc

- Fungus

Fluid is an especially important factor to consider. Parts inside of an automobile or machine are likely to be exposed to some kind of hydraulic fluid or oil.

The level of resistance to these factors lies in the chosen elastomer. Natural rubber, for example, is not able to withstand extremely high temperatures. Silicone, on the other hand, has high resistance in just about each one of these categories. Understanding how an elastomer reacts to environmental conditions is extremely important to how it performs. Be sure to choose a sandwich mount that works best for the desired application.

Do you really know everything about designing with rubber parts?

Get a free and valuable resource for finding or custom designing the exact part you need.

Sandwich Mount Installation and Static Load

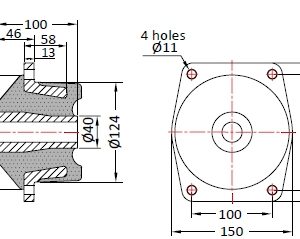

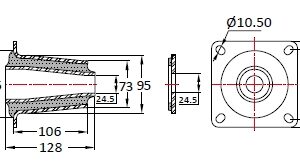

An important consideration when choosing a sandwich mount is the installation process and static load. When you meet with our RPM Industrial Rubber Part we will help determine how the mount will be installed. Using the data points that you provide such as static load and disturbing frequency, we can tell you exactly what mount you need.

Here are some data points from our Engineering Data for Vibration and Shock Isolator Questionnaire to get you started:

- Equipment weight

- C.G. location relative to mounting points

- Sway space

- Maximum mounting size

- Equipment and support structure resonance frequencies

- Moment of inertia through C.G. for major axes

- Fail-safe installation requirement

Take a look at our Selecting a Vibration Shock Isolator guide and scroll to Figure 13 for the full questionnaire. Knowing the answers to these kinds of questions will help you determine which sandwich mount is best.

Types of Vibration Isolating Sandwich Mounts

There are many types of isolators that may be chosen for vibration damping. Choosing which one of these to use depends on the application and vibration requirements of the machinery. They include:

- UNC thread, male-male

- Metric thread, type 1

- UNC or Metric thread, type 2

- UNC or Metric thread, type 3

- UNC or Metric thread, type 4

- UNC or Metric thread, type 5

- Vibration foot

- Vibration buffer

Fully bonded are the most popular type of isolator. These are also known as sandwich mounts. In addition to all of the isolators that are available, sandwich mounts alone have a few different kinds:

- LORD Flex-Bolt™ sandwich mounts

- Square pad mounts

- Large shear mounts

- Rubber flex sandwich bobbin mounts

Each of these mounts is best for a specific use. For example, bobbin mounts may be used as a vibration foot or damper while square pad mounts are best for use in compression orientations.

Take a look at our Application Selection Guide to learn what kind of mount is best for your needs.

Quality Sandwich Mount Supplier

Looking for a rubber manufacturing company that provides not only parts but consulting? RPM Industrial Rubber Parts is your partner for finding the right solution to pLooking for a sandwich mount supplier with high-quality products and a team of engineers ready to help? Then you need RPM Industrial Rubber Parts.

We know that choosing the right sandwich mount requires the right data and engineering knowledge. That’s why we are committed to providing one-on-one service and guidance. At RPM Industrial Rubber Parts, we offer only the best. This includes LORD Flex-Bolt™ sandwich mounts and highly experienced engineers. Whether you need a custom or standard molded rubber part, we’ve got you covered. To get in touch with our team at RPM Industrial Rubber Parts, give us a call at (888) 842-5668 or contact us online.

Related Resource

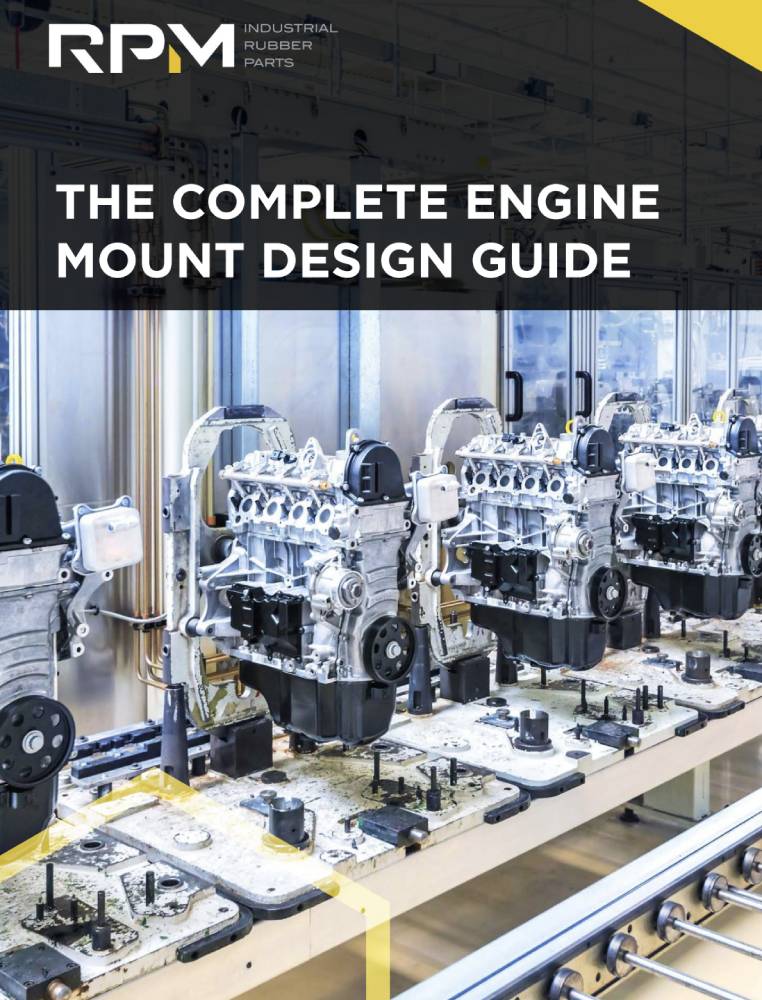

The Complete Engine Mount Design Guide

Are you using the right engine mount for your system? Avoid the downfalls of choosing the wrong engine mount with our guide to engine mount design.