To understand vibration mounts, it’s first helpful to understand the problems they have been developed to solve.

Within on and off-highway vehicles, machinery, and equipment, vibration impacts introduce large forces and intense stresses that can lead to degraded performance, expensive repairs, and premature failure of support mechanisms.

Both internal combustion engines (ICE) and electric motors are large, concentrated masses that, if not adequately supported, can cause potentially hazardous vibrations to be transferred to supporting structures.

However, effective engine support and reduced looseness can limit structural vibrations, while proper engine mounting and accurate support design can mitigate engine vibrations.

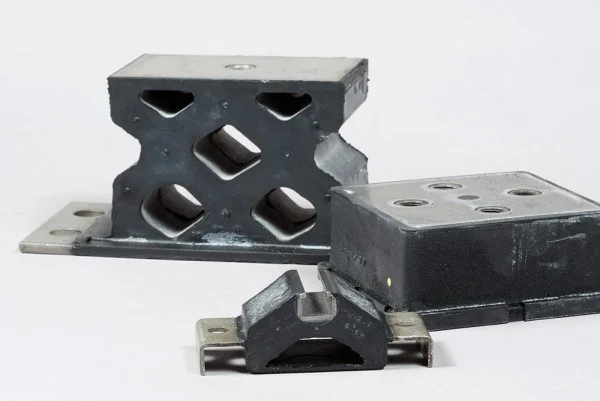

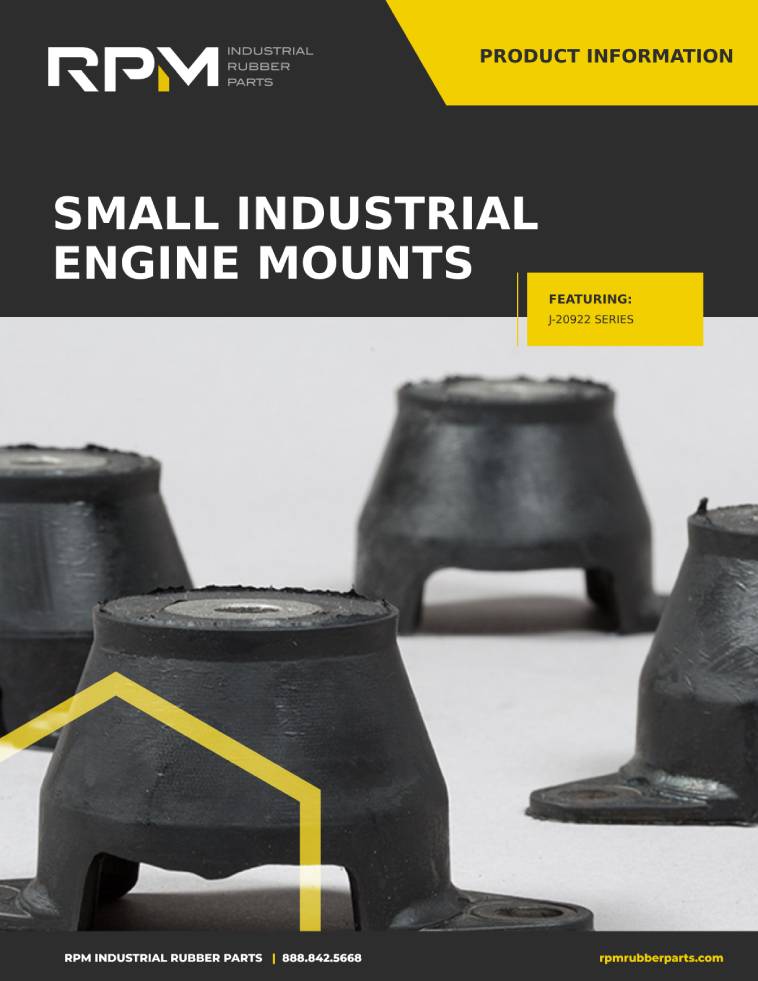

Vibration mounts are commonly used in machinery as passive isolation to relieve vibrations posing operational challenges and damaging equipment. These mounts offer a passive technique to isolate or dampen vibration.

What’s in a Name?

Although they all function to either isolate or dampen vibration, there are about as many different names for vibration mounts as there are applications. Vibration mounts come in various shapes, sizes, and materials.

Different Names for Vibration Mounts

- Anti-Vibration Mount

- Vibration Dampening Mount

- Isolation Mount

- Mounting Flange

- Flange Mount

- Vibration Isolation Mount

- RA Vibration Mount

- RAEM Vibration Mount

- Cup Mount

- Transit Mount

- Cushy Float Mount

- Bell Mount

- And more…

You get the idea. Mounts are vital to vibration mitigation, and their widespread deployment clearly indicates their value and significance.

Antivibration mounts and other vibration-control products reduce the noise and vibration frequency caused by everyday machinery, reducing vibration and shock while protecting valuable equipment from damage.

Do you really know everything about designing with rubber parts?

Get a free and valuable resource for finding or custom designing the exact part you need.

Rubber and Spring Mounts

Most vibration mounts are made of rubber, springs, or a combination of both. These passive vibration isolation solutions are based on vibration theory.

These materials offer excellent shock absorption and vibration-dampening properties and are used in various domains and industries.

Passive vibration isolation mounts are cost-effective, high-performing, and easy to install. They offer optimum performance alongside nearly unlimited flexibility and customizability. Vibration reduction can often reach up to 95%.

Rubber and other elastomeric solutions are easy to install, require limited manufacturing time, and are loaded in shear to offer excellent vibration absorption. Their flexibility and durability make them perfect for mobile and static applications.

Can a bad motor mount cause vibration?

While much “bad” or “undesired” vibrations result from the natural and healthy functioning of heavy vehicles and machinery, there are some cases where the problem can be easily diagnosed and fixed by simply replacing an old or worn-out mount.

Increased vibrations are one of the most apparent symptoms of a damaged or worn-out engine mount. If an engine mount is damaged, its anti-vibration properties will weaken. Often, an increase in vibrations will lead to an engine making more sound than usual, indicating that the engine is in danger of extreme damage if the vibration and its source are allowed to continue.

Choosing the Right Vibration Mount

Selecting the perfect vibration mount requires careful consideration of various factors. Start by assessing the specific application, including the equipment’s weight, size, and operating environment. Consider the frequency range and amplitude of vibrations to be isolated, as well as any directional requirements. Evaluate the desired level of isolation and damping needed for optimal performance. Additionally, factor in considerations such as cost, maintenance requirements, and durability. Consult with experts at RPM who specialize in vibration isolation technology to ensure you choose the right mount tailored to your precise needs.

To get in touch with our team at RPM Industrial Rubber Parts, give us a call at (888) 842-5668 or contact us online.

Related Resource

The Engineer’s 7-minute Guide to Rubber Molded Parts

Our free resource is a quick-reference guide to help you determine if exploring a rubber part is right for your application.