In today’s fast-paced industrial landscape, the role of expertly crafted rubber products cannot be overstated. These components are the unsung heroes in isolating vibrations, a critical factor in safeguarding both sophisticated machinery and the invaluable operators behind them. This protective measure is indispensable across leading sectors where the machinery's complexity and the demand for precision run high.

Downtime due to equipment failure is more than an operational hiccup; it's a significant financial setback stemming from lost productivity and escalated maintenance costs. Often, the root cause is traced back to inadequate vibration isolation. Excessive vibration not only accelerates the wear and tear of internal components but also compromises the machinery's overall performance and lifespan. Implementing high-quality rubber mounts, bearings, and suspension systems is crucial in mitigating these issues, thereby enhancing equipment durability and operator comfort.

Understanding the intricate requirements of specialized machinery, RPM Rubber Parts stands at the forefront of rubber manufacturing. Our expertise lies in designing and delivering rubber components that meet the exacting needs of your applications. Let us navigate you through our comprehensive solutions, ensuring your equipment operates at its peak while minimizing discomfort and downtime.

Here are the topics covered in this guide:

Many industries require rubber manufacturing services for different equipment purposes. Continue reading for information on the following:

Rubber Manufacturing in Today’s Industries:

|

Rubber Manufacturing & Mining:

|

Symptoms of Rubber Flaws in Equipment:

|

Rubber Manufacturing & Mass Transit:

|

Rubber Manufacturing & Agriculture:

|

Rubber Manufacturing & Military:

|

|

Rubber Manufacturing & Medical:

|

|

RPM: Providing Expert Rubber Manufacturing for Every Industry

Rubber needs for equipment are different from industry to industry and from company to company. Whether you are looking for replacement critical components or new parts for innovative designs, RPM Industrial Rubber Parts can help.

Ready to talk to one of our knowledgeable experts? Click on the link to contact us: https://www.rpmrubberparts.com/contact

Rubber Manufacturing in Today’s Industries

Although there are a vast amount of industries that take advantage of rubber’s usefulness, there are a handful that stand out from the rest. Take a look:

These industries are at the forefront of producing out-of-the-box equipment manufactured to provide ultimate efficiency. From excavators to armored tanks, the larger the emphasis on utilizing rubber, the better the outcome.

There are some introductory considerations anyone in any industry should understand about the role and importance of rubber for vibration isolation. Using quality isolating rubber parts is so much more than just implementing a design. When vibration frequencies are limited in machinery, it benefits everyone.

Equipment is designed for longevity, but without the proper vibration control products, parts work incorrectly or wear down fast. Rubber mounts help to isolate vibration and protect valuable equipment, enhancing its long-term use and value. Using machinery with rubber mounts will decrease equipment downtime by putting less stress and wear on critical components, such as engines.

New Technology

As technology improves, people in every industry are looking for efficient, streamlined operation and enhanced automation. This can mean new sensors and electronic systems that provide additional information about the equipment. When sensors are subject to too much vibration, they are more likely to need frequent repairs and replacements. Implementing rubber mounts can make an enormous difference in the continuing effectiveness of these parts.

Operator Safety

In the realm of industrial operations, the significance of operator safety cannot be overstated. At the heart of maintaining a safe and productive work environment lies the integrity of the machinery used. Ill-functioning equipment not only hampers job performance but also poses serious health risks due to prolonged exposure to vibrations. Moreover, the well-being and morale of workers are directly impacted by the quality of their working conditions. It's here that the expertise in rubber manufacturing becomes not just relevant but essential.

High-quality rubber parts, designed for optimal vibration and shock absorption, play a pivotal role in safeguarding operator safety. By integrating superior rubber components from RPM Rubber Parts into equipment, manufacturers and end-users demonstrate a commitment to prioritizing human factors in their operations. This approach underscores the belief that the value of machinery is realized fully only when it enhances the safety and productivity of its operators.

The selection of the right rubber mounts involves a meticulous process, beginning with a comprehensive analysis using the Harmony model. This includes:

- Static Analysis: Evaluating the engine's weight and torque to confirm the mount's capacity to withstand the load.

- Dynamic Analysis: Assessing natural frequencies and potential engine disturbances to ensure optimal mount performance.

Upon completing these analyses, our team is equipped to identify the most suitable engine mounts for any given application. This decision-making process is critical; incorrect analysis can exacerbate issues rather than resolve them. It ensures that each system benefits from complete isolation, tailored to its operational demands. While selecting a rubber part from a catalog might seem straightforward, the true value lies in a consultative approach. Engaging with our engineers for a detailed analysis ensures that your equipment receives precisely what it needs to operate safely and efficiently.

At RPM Rubber Parts, we believe that the journey to optimal equipment performance begins with a thorough understanding of your needs, followed by the application of our specialized rubber manufacturing capabilities. This dual-step approach not only enhances equipment reliability but also, and more importantly, puts operator safety at the forefront of industrial operations.

Equipment Durability and Rubber Parts

Deciphering the underlying causes of equipment durability challenges can often be a complex task. However, a closer examination of rubber mounts and their condition can offer insightful clues into potential issues. At times, the absence or failure of a mount or isolator might be the culprit behind these challenges.

Signs of deteriorating rubber components include:

- Premature component failures, triggered by unmitigated shock and vibration.

- Increased operator discomfort or fatigue, directly impacting productivity.

- Breakages in engine components, a clear sign of inadequate protection.

- Elevated levels of noise and/or vibration, indicating poor vibration control.

Identifying these symptoms early on is crucial in tracing back to issues of uncontrolled vibration. A common scenario illustrating this is when multiple engine-adjacent components fail, suggesting that the engine itself lacks proper mounting and isolation. Without effective vibration control, the engine's movements can lead to excessive wear and tear on surrounding parts, ultimately compromising the equipment's integrity.

RPM Rubber Parts specializes in the art and science of rubber manufacturing, offering advanced solutions for vibration isolation. Our expertise in designing and producing high-quality rubber mounts and isolators is at the forefront of extending equipment lifespan and enhancing operational efficiency.

To delve deeper into how our vibration isolation solutions can benefit your industry, we invite you to reach out to us. Continue exploring our insights to grasp the full extent of how rubber components are pivotal in maintaining equipment durability across various sectors.

Rubber Manufacturing & Construction

In the bustling world of construction, the machinery at the heart of every project—from towering office buildings to the intricate repair of roadways—relies heavily on the unsung hero of durability and efficiency: rubber manufacturing. The critical role of rubber parts, designed to perfection, ensures that these machines operate at their peak. However, when these rubber mounts and components are overlooked, incorrectly installed, or simply not up to par, the repercussions are immediate: increased maintenance, diminished operator comfort, and a noticeable drop in productivity.

Consider the powerhouse behind most construction vehicles: large, diesel engines. Their sheer size and power mean they're capable of emitting vibrations at frequencies that can not only disrupt the harmony of the machinery but potentially lead to catastrophic failures. This scenario underscores the indispensable need for high-quality rubber manufacturing in safeguarding equipment integrity and functionality.

Amidst a backdrop of material shortages, as reported by the National Association of Home Builders, with a staggering 90% of builders facing a plywood scarcity, the importance of maximizing equipment uptime and productivity has never been more pronounced. This challenge is compounded by a significant labor shortage in the construction sector, as highlighted by Construction Dive, with half a million positions unfilled. The quality of the work environment, heavily influenced by the level of vibrations and noise, plays a pivotal role in not only retaining but also attracting the workforce. A serene and comfortable setting boosts productivity and morale, in stark contrast to the detrimental effects of a noisy, harsh workplace.

Addressing these challenges head-on, the application of precision-engineered vibration-isolating rubber parts emerges as a game-changer. From engine mounts to flex sandwich mounts, the array of rubber components tailored for construction equipment is vast. Each is designed with the dual purpose of minimizing vibration frequencies and extending the lifespan of the machinery. This strategic integration of rubber manufacturing into construction not only enhances the operational efficiency of equipment but also significantly improves the working conditions for the labor force.

The essence of rubber manufacturing in the construction industry cannot be overstated. It is the foundation upon which the reliability and durability of construction equipment rest. By prioritizing the use of superior rubber mounts and components, we pave the way for more resilient machinery, happier workers, and ultimately, more successful construction projects.

Want to learn more about engine mounts? Take a look at this blog: What is an engine mount?

Construction Equipment Types

The construction industry is a diverse and dynamic field, where each project demands a unique set of tools and machinery. This diversity is reflected in the wide array of specialties and crafts that make up the sector, each relying on specific equipment to get the job done. Consequently, a construction fleet might encompass a varied assortment of machinery, tailored to meet the unique challenges of each task. Among the most commonly deployed construction equipment are:

- Backhoes

- Excavators

- Graders

- Pile Drivers

- Bulldozers

- Trenchers

- Wheel Loaders

- Compactors

These machines, while diverse in their functions, share a common need for precision-engineered rubber components. The demands placed on this equipment—ranging from the rigorous vibration control of a pile driver to the suspension requirements of a heavy-duty excavator—highlight the critical role of rubber manufacturing in the construction industry. Each piece of equipment necessitates rubber parts that are not only a perfect fit for its specific engine or cabin but also robust enough to protect against the rigors of heavy use, preventing premature wear and ensuring longevity.

Rubber manufacturing, with its ability to produce components tailored to the nuanced requirements of different construction machinery, stands as a cornerstone of equipment reliability and efficiency. By providing custom solutions for vibration control, suspension, and more, high-quality rubber parts play an indispensable role in the smooth operation and extended service life of construction vehicles. This specialized approach to rubber manufacturing ensures that each machine, regardless of its role on the construction site, operates at its peak performance, contributing to the overall success and productivity of construction projects.

Vibration Isolation for Construction Equipment

Among the myriad advantages offered by premium rubber components, vibration control stands out as a critical factor in safeguarding construction equipment, architectural integrity, and workforce well-being. The strategic isolation of disruptive vibrations is essential in preventing damage to both machinery and the structures they help create.

Often underestimated, the impact of vibrations from construction machinery can lead to significant damage, including the cracking of facades and compromising the structural integrity of buildings. Such issues not only pose safety risks but can also escalate project costs and timelines.

The integration of specialized rubber mounts and components is pivotal in maintaining the seamless operation of essential machinery parts. Rubber products are integral to a variety of systems within construction equipment, playing a crucial role in enhancing performance and durability. Key applications include:

- Valve Body Mounts

- Rear Engine Mounts

- Axle Suspension Systems

- Steering Stops

- Transmission Mounts

- Viscous Cab Mounts

This enumeration merely introduces the extensive range of rubber vibration isolation products embedded in construction machinery. A deep understanding of vibration isolation principles is paramount in addressing these challenges effectively. By mitigating vibration-related issues, construction projects can proceed with minimal disruption, ensuring the longevity of equipment and the safety of structures and personnel.

For a deeper dive into the role of rubber in enhancing the resilience and efficiency of construction equipment through advanced vibration isolation techniques, we invite you to explore further insights on our blog.

This list only scratches the surface of the amount of rubber vibration isolating products found in construction equipment. Understanding vibration isolation theory and why it matters is the best way to combat issues and ensure smooth operation. To learn more about rubber in the Construction Industry, read our blog.

Rubber Manufacturing & Agriculture

It is critical that agricultural equipment is ready to roll when harvesting or planting time arrives. According to Frontu, farm machinery and agriculture trends are trending to more sustainable, tech-first, and reliable farming equipment to meet food demands.

Agricultural machinery is constantly shaking and rattling, which puts wear and tear on the internal components. To ensure that agricultural machinery meets new sustainability goals by lasting longer, manufacturers should include the use of vibration-reducing rubber parts.

The desire for more technological machinery also requires new types of vibration control in equipment. Sensors and screens are extremely sensitive to vibration. Without isolating mounts, these key components can malfunction.

Agriculture Equipment Types

Hydraulic motor mounts contain a combination of rubber elastomer and a fluid filled chamber to dampen energy. In basic terms the mount has a fluid filled internal chamber where the fluid is forced through an orifice in order to dampen energy rather than being only elastomer. The result is a much higher factor of damping characteristics that can be achieved over just using only elastomers.

One of the main benefits is to provide a much more specific damping profile for application as the fluid chamber can be tuned to the application. This requires a bit more analysis and application work. However, it is a great choice for applications that demand specific performance. These engine mounts are much more complex than other kinds of mounts due to the addition of the hydraulic fluid.

Hydraulic mounts are most common in vehicles with three to four cylinders as these provide the greatest amount of noise and vibration challenges.

Vibration Isolation for Agriculture Equipment

The two most concerning issues of vibration in agriculture equipment are similar to any other industry: operator safety and comfort and machine protection. Using vibration isolation parts eliminates these problems simultaneously.

When farmers have to operate heavy machinery for long periods of time, they can become uncomfortable from the loud noise and the constant vibration. In fact, according to a study completed at the University of Iowa, there is a correlation between agriculture machinery vibration and back pain among farmers. To combat this issue, manufacturers should use high-quality rubber mounts for engines, cabs, the transmission, and other major components of farming equipment.

Less vibration means fewer health risks for farmers and ease of use for equipment for plowing, planting, harvesting, and maintaining land.

If manufacturers want to ensure that farmers and farming corporations become repeat customers, they need to build equipment that lasts. Using rubber mounts is a proven way to preserve the delicate balance of purpose-built agriculture machines. To learn more about rubber in Agriculture, read our blog.

Mining Equipment Types

Because of the conditions, mining equipment is often very specialized. These are only a few of the equipment types used in the mining industry:

- Bolter

- Personnel carriers

- Utility vehicles

- Boom lift

- Rockbreaker

- Sprayers and cannons

- Explosive chargers

This list is sure to change in the future as the industry begins to rely more on electric vehicles and robotics for mining. With these changes, there will be adjustments in how rubber is utilized in the industry. At RPM, we plan to be on the cutting edge of new developments, always meeting the twofold objective of operator safety and streamlined machine operation.

Vibration Isolation for Mining Equipment

Electric vehicles and robotics are more sensitive than traditional vehicles, especially when it comes to environmental conditions. Even mining equipment that continues to use diesel engines requires low-frequency conditions to limit damage. Using rubber mounts to reduce shock is the best way to keep these machines in use for as long as possible, with little downtime in between.

Engines and electronic systems are not the only parts of machinery that require vibration isolation. These are some rubber parts that reduce vibration in other components of equipment.

- Hood mount

- Drum mount

- Mirror tuned vibration absorber

- Battery mount

- Steering column mount

- Steer-by-wire feedback device

There are endless ways in which rubber mounts and parts can reduce harmful frequencies. As the mining industry heads towards sustainable machinery, vibration isolation needs will become more focused on protecting electronic components too. To learn more about rubber in the Mining Industry, read our blog.

Rubber Manufacturing & Mass Transit

Billions of people rely on mass transportation every day. Of course, with so many people relying on these vehicles, they must be mechanically sound. In these systems, some of the most important components are the engines, transmission, and brake systems.

Sensitive components require shock and vibration control, using rubber parts to isolate harsh, naturally occurring rattling and shaking. When mass transit equipment is manufactured with a variety of rubber parts for protection, there are many benefits:

- Less required maintenance

- Fewer breakdowns

- More comfortable passengers and operators

- Longer lasting parts

- Fewer replacements

A broken down bus or rail car is an inconvenience to everyone. With RPM Industrial Rubber Parts, manufacturers have the opportunity to ensure that mass transportation is reliable, comfortable, and safe.

Mass Transit Equipment Types

There are many kinds of vehicles and equipment that the public uses to get around. According to the American Public Transportation Association, here are some of the most common forms of mass transportation:

- Streetcars

- Buses

- Ferries

- Monorails

- Subways

- Commuter trains

- Light rail

- Cable cars

Although they all serve a similar purpose, each is designed for its conditions and use case. A monorail may have some similar components to a bus, but they clearly have very different specifications for braking and steering, among other functions and features. The standard need for vibration isolation is a shared trait.

Vibration Isolation for Mass Transit Equipment

Manufacturing mass transit equipment is an ever-evolving activity. One of the key tasks is designing the vehicle so that riders and operators are equally comfortable. The other is configuring the equipment to keep sensitive parts safe from disturbing frequencies.

Mass transportation vehicles use all sorts of GPS systems, tracking devices, and other electronic sensors that are able to display relevant information to drivers/operators and passengers. As mass transport gets more sophisticated and technologically advanced, there are more parts that require protection.

Rubber mounts are the perfect tool for this. Mounts work by isolating the part, such as an engine or sensor, so that any natural vibrations only affect the part minimally. Mounts can be used on seats, electronic systems, steering systems, transmission, wheel suspensions, and more. Ready to read more about rubber in Mass Transit? Read our blog.

Interested in learning more but not sure where to start? Take a look at our blog about the top 4 questions we get asked about selecting the right vibration isolation mount.

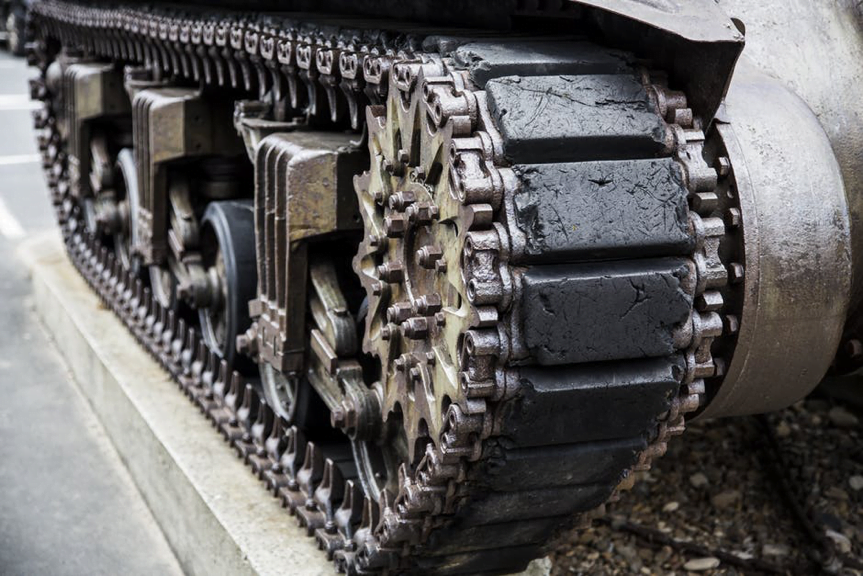

Rubber Manufacturing & Military

Manufacturing military equipment and machinery may require a higher level of customization and specification than other types of equipment. Defense grade machinery needs to be equipped to handle the following:

- Rugged terrain and adverse conditions

- Heavy gunfire and explosions

- Artillery additions

- Personnel safety

- GPS systems and other electronics

Of course, these are not the only specifications that military equipment must meet. Each vehicle has to handle different levels of risk and meet safety criteria.

Non-combat-related health risks are associated with mechanical shock in military vehicles. The article “Vehicle Exposure and Spinal Musculature Fatigue in Military Warfighters,” published in the Journal of Athletic Training shows this correlation. In fact, the effects are similar to those seen in farmers and construction workers who handle equipment and machinery.

Rubber parts are useful for defense equipment. They can help to protect personnel, artillery, electronic systems, and more.

Military Equipment Types

There is an increasingly large number of different defense equipment types. Each branch of the military has its own specialties that require different machinery needs. For example, the Navy uses amphibious vehicles and water vessels. Here are some more general military equipment types:

- Jets, helicopters, and other aircraft

- Ships and submarines

- Tanks and armored combat vehicles

- All-terrain vehicles

- Multipurpose vehicles

These different types of equipment all need protective rubber parts. From the wheel suspension to the seats to firearms/offensive mechanisms, almost every aspect of these machines requires isolating properties.

Vibration Isolation for Military Equipment

Consider the dangerous conditions that many military vehicles and equipment face. Explosions, gunfire, rough terrain, and weather are only a few of the risks posed to defense equipment.

Not only does the equipment need to withstand these conditions, it also needs to be designed and manufactured to keep the personnel within it safe. Military equipment is tested using the Department of Defense MIL-STD-810, called the Environmental Engineering Considerations and Laboratory Tests. When equipment is tested using these standards, one of the most important considerations is how well it can withstand shock, noise, and vibration.

The concept of vibration isolation gains new meaning when applied to military equipment. The extreme forces that these vehicles endure sometimes means that a standard rubber part won’t cut it.

Custom parts are an excellent option for equipment that handles more than the average vehicle or machine. At RPM Industrial Rubber Parts, we have experts who are ready to work with manufacturers to find the perfect custom parts solution. Want to learn more about rubber manufacturing for the Military? Read our blog.

To turn your ideas into reality, contact our team at (888) 842-5668 or online: www.rpmrubberparts.com/contact

Rubber Manufacturing & Medical

The medical industry is at the forefront of producing new, innovative technologies and devices designed to preserve lives. People around the world rely on these medical devices for short-term and long-term care. Each device has manufacturing parameters that are followed to the letter. In order to do the task the device was designed to do, there cannot be any flaws that may cause external interference.

Rubber manufacturing plays an important role in these technologies. In fact, rubber and silicone are two common materials for medical equipment.

Medical equipment performs or supports life-saving procedures. Standard, time-tested, and well-researched medical devices use rubber of all kinds to achieve absolute precision. Rubber is also at the forefront of new designs in this field: Custom fabrication of molded rubber parts is a key step in manufacturing new medical devices. Rubber parts may include seals, tubing, and mounts.

As the medical industry continues to implement groundbreaking technologies and devices, rubber manufacturers will mold and fabricate rubber materials.

Medical Equipment Types

Medical equipment seems to constantly evolve and push the limit of what devices can do. The different kinds of medical equipment is an extensive list. These are some of the most common equipment types that utilize rubber in some capacity:

- Pumps for oxygen and infusion pumps

- Sensors and electronic systems

- Precision equipment

- IV tubing

- CT scanners, x-ray machines, and MRI machines

- Centrifuges and laboratory equipment

Medical professionals save lives and rely on finely tuned equipment to do so.

Vibration Isolation for Medical Equipment

It’s important that medical equipment can effectively function for a long time without maintenance or parts replacement. Additionally, it’s important that there aren’t any external factors that are negatively impacting the results of the equipment.

From reducing sound to improving device performance, rubber mounts and bearings are present in all types of medical devices.

In laboratory equipment, such as centrifuges, excessive vibration can disrupt processes and cause adverse or inaccurate results. Rubber mounts reduce vibration. With the right vibration isolation, devices can do what they were meant to do without interference.

Medical device issues often stem from flaws in the rubber components. This is why it is so important to consult experts when manufacturing medical equipment. Learn more about rubber in the Medical Industry here.

There are many different rubber sandwich mount applications that are used to improve medical products and devices: learn more here.

RPM: Providing Expert Rubber Manufacturing for Every Industry

There are clearly overlaps of need in all of these industries. The bottom line is that when rubber parts are effectively designed and manufactured, there are benefits across every sector. Using isolation mounts increase equipment durability, improves operator comfort, and reduces downtime.

Depending on the industry, type of equipment, and stage in the manufacturing process, there are different needs for rubber parts.

At RPM Industrial Rubber Parts, we can help. Take a look through our standard parts catalog or give us a call to see if we have what you need. If we don’t, let us know how we can help you get it. We have an expert custom rubber part team of engineers and designers ready for you.

If you have a new, innovative idea and need a partner in rubber design, we can do that too. The experts at RPM love being a part of the design process, especially for inventive equipment that requires creative and advanced solutions.

With unparalleled customer service and only the highest quality materials, RPM Industrial Rubber Parts is the partner you need. Give us a call at (888) 842-5668 or contact us online.

.jpeg)