Download Our Rubber Compression Molding Guide

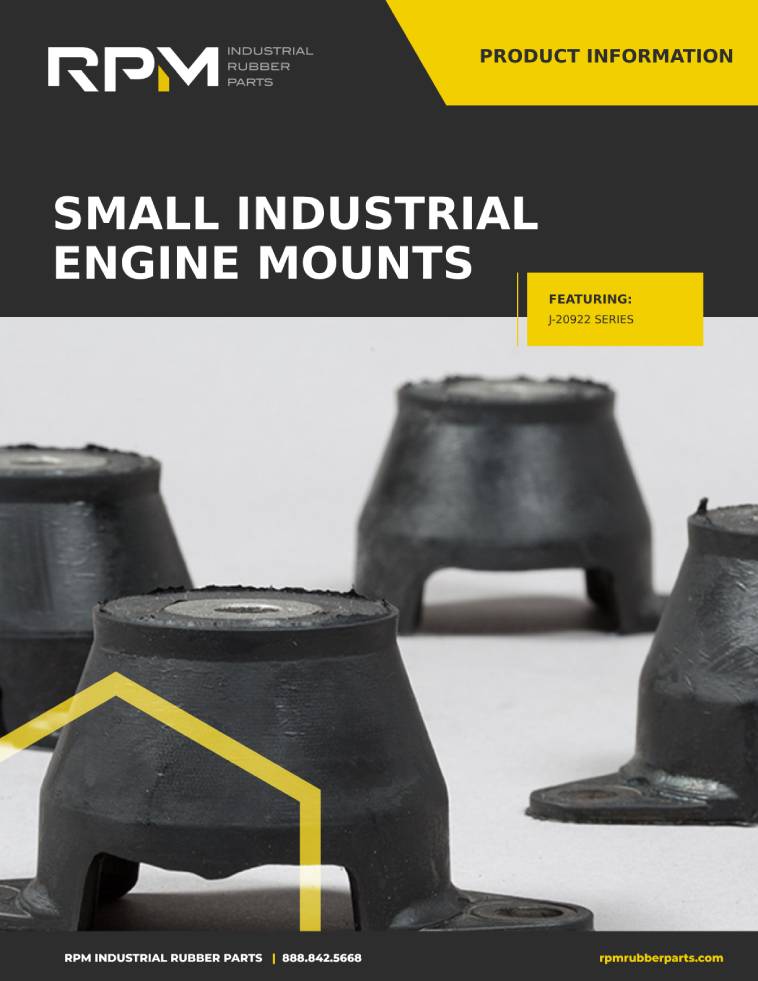

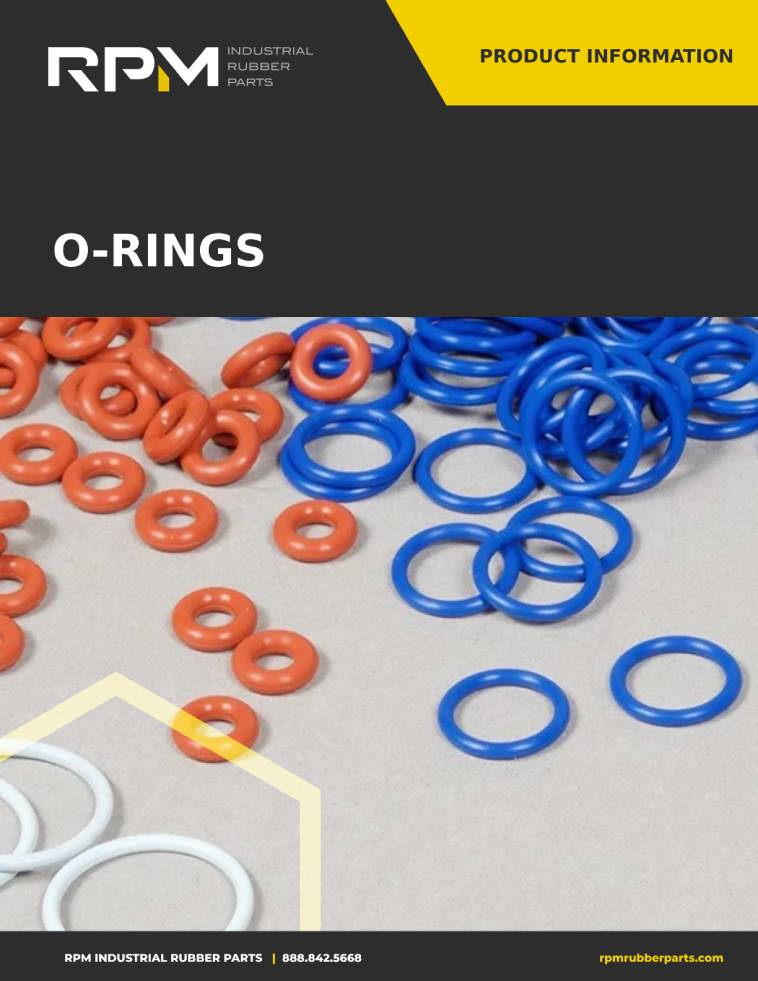

Rubber parts function to solve a problem. Generally, that problem is unwanted vibration or a sharp edge that could cause damage to another part; in these cases, a rubber piece serves to isolate, seal and protect. Rubber’s elasticity, high resilience and tensile strength make it the perfect material to address structural and functional issues in physical systems across a wide range of industries. By creating the ideal rubber part to solve a particular problem, rubber parts manufacturers create value for companies, saving them time, money and additional processes.

From the automotive industry to the medical industry to the agricultural industry, rubber parts play an essential role in smooth operations. Both standard and custom rubber parts are manufactured through a process called molding. There are three main types of molding, which will be touched on in this article. Of these, rubber compression molding is arguably the fastest, most economical and best established method for producing simple, precise products. A tried-and-true method, rubber compression molding allows customers to get the rubber parts they need without wasting resources.

Whether you need a large run of standard parts, a preliminary run of custom parts or a prototype for your next big idea, RPM Industrial Rubber Parts is here to help. Interested in rubber compression molding? Our expert engineers can analyze your product model, choose the best molding method and manufacture it to the highest standard of quality.