While there may be a wide array of rubber parts and components to choose from for a product, sometimes it’s difficult to find the exact piece that you need. One of the ways that manufacturers combat this problem is through custom rubber molded parts. This is a great way to get the rubber parts that you need with the right dimensions, color, material, weight, durability and more.

There are many reasons why a manufacturer may choose custom molded rubber parts:

- Tailored Design: Custom molded rubber parts can be precisely engineered to fit specific shapes, sizes, and specifications required for the intended application. This ensures optimal functionality and compatibility with existing components.

- Enhanced Performance: Custom rubber parts can be formulated with specific material properties to meet performance requirements such as temperature resistance, chemical compatibility, durability, and vibration damping. This customization ensures that the parts perform effectively in their intended environment.

- Cost Efficiency: While the initial tooling and setup costs for custom molding may be higher than off-the-shelf options, custom rubber parts can often provide long-term cost savings by reducing assembly time, minimizing waste, and improving overall efficiency in production processes.

- Quality Control: Custom molding allows manufacturers to have greater control over the quality and consistency of the parts produced. This can lead to fewer defects, better reliability, and improved customer satisfaction.

- Innovative Solutions: Custom rubber molding enables manufacturers to innovate and develop unique solutions to address specific engineering challenges or to differentiate their products in the market. This flexibility encourages creativity and fosters product innovation.

- Reduced Assembly Complexity: By designing custom molded rubber parts to integrate multiple functions or components into a single part, manufacturers can streamline assembly processes, reduce the number of components needed, and minimize points of failure.

- Brand Identity: Custom molded rubber parts can be designed to reflect the manufacturer’s brand identity through unique shapes, colors, textures, or logos. This branding can help differentiate products in the marketplace and enhance brand recognition.

Do you really know everything about designing with rubber parts?

Get a free and valuable resource for finding or custom designing the exact part you need.

Industries and Applications of Custom Molded Rubber

Many industries utilize custom molded rubber parts for all kinds of applications. From grommets to tubing to mounts, there are no limits when it comes to custom rubber molding. Here are only a few of the industries that use this service:

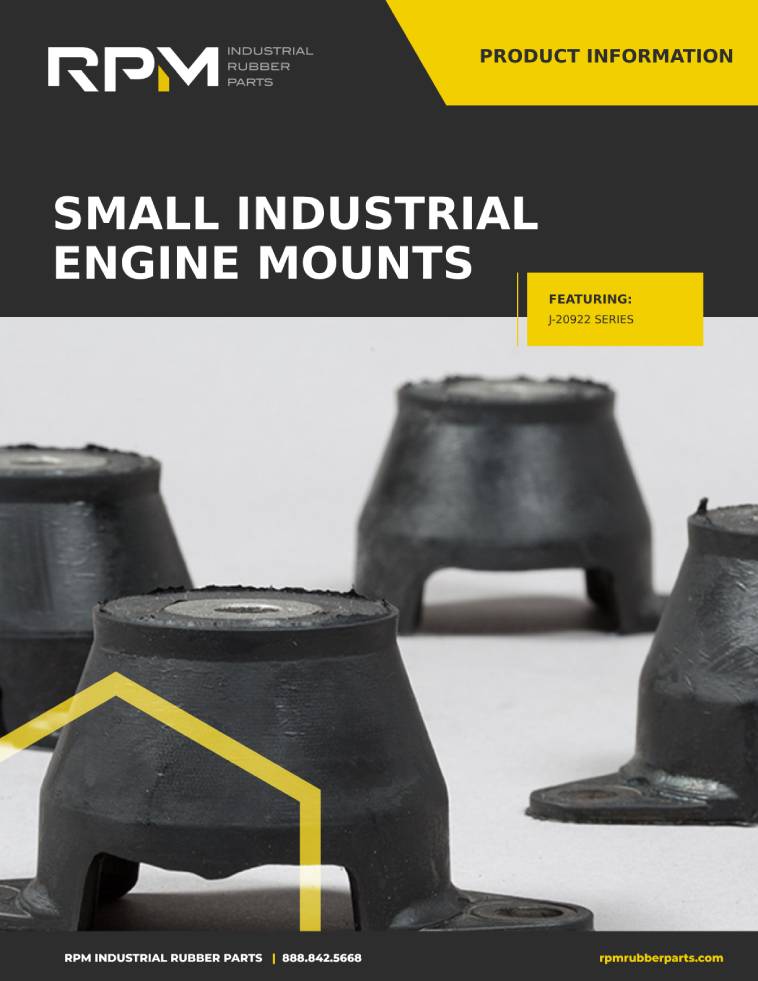

- Automotive: engine mounts, door and window seals, vibration reduction, extruded tubing

- Construction: noise control, belts, buttons and knobs, engine mounts, bushings

- Defense: vibration reduction mounts, tracks and belts, rifle or equipment isolation, reduce metal to metal contact.

- Mass Transit: bumpers, grommets, window and door seals, extrusions and tubing

- Medical: catheters, gaskets, tubing, strain relief, extrusions, syringes, diaphragms, cords

- Agriculture: vibration reduction, noise control, window and door seals, engine mounts, bushings, bumpers, extrusions

These are not the only industries that use custom rubber molding services, nor are these the only applications. Often, custom rubber molding services are customer driven. This means that the customer comes up with the idea, aids in the design process and approves the prototype. Custom rubber parts do not have to be based off of standard parts such as seals or bushings. These parts, and their functions, can get as unique as the customer requires. If you can think it – we can make it – let’s discuss!

Custom Rubber Molding Benefits

Manufacturers use custom rubber molding services because there are plenty of pros. The main benefit is the ability to choose the properties of the parts. Take a look at some other benefits that come with custom rubber molding:

- Ability to produce from one prototype to full volume, sometimes ranging in the millions

- Depending on the design, there are different molding capabilities to choose from

- Ability to adapt the part to the conditions it will be in through the choice of material and thickness

- Better aesthetic customization with color and texture choices

- Ability to complete rubber to metal bonding if needed for the part

- Perfect for detailed parts that require high precision and accuracy

- Stay involved every step of the way from idea to final product

There are many more benefits that customers receive when they utilize custom rubber molding services.

Capabilities of Custom Molded Rubber

There are many capabilities for molding custom rubber parts. Just about any type of rubber molding process can be used, however some processes are preferred over others depending on the part. Selecting a manufacturing process will depend on the raw material/rubber material you start with and the intended use for your custom molded products. The options for treating rubber or a rubber compound include:

- Compression Molding: another popular method for custom part production, this one is best for low volume and low intricacy.

- Injection Molding: this is one of the most widely used and preferable methods of custom part production. It is an excellent choice for high volume parts that require precision.

- Transfer Molding: this molding process is best for low volume part production. It is a good choice for intricate custom parts.

With custom part production, rubber companies can also complete the design in one of two ways: prototyping or reverse engineering. Take a look at the difference:

- Prototyping: this is the process used for completely unique designs that are not based off of a different part.

- Reverse Engineering: this process is typically used when a part has been discontinued, become more expensive or some other reason for discontinued use by the manufacturer. The part will be reverse engineered so that the customer has a nearly identical part with the properties that they are looking for.

To find out more about custom rubber molding capabilities, talk with a provider or continue reading.

High Quality Custom Rubber Molding Service

At RPM Industrial Rubber Parts, customers can choose from a wide variety of standard parts or choose to order a custom molded rubber part. We offer only the highest quality parts and excellent customization capabilities. From grommets to vibration isolating parts, our team is ready to provide excellent service. Here are some of the standard parts that we offer:

- Tubing

- Bumpers

- Bushings

- Mounts

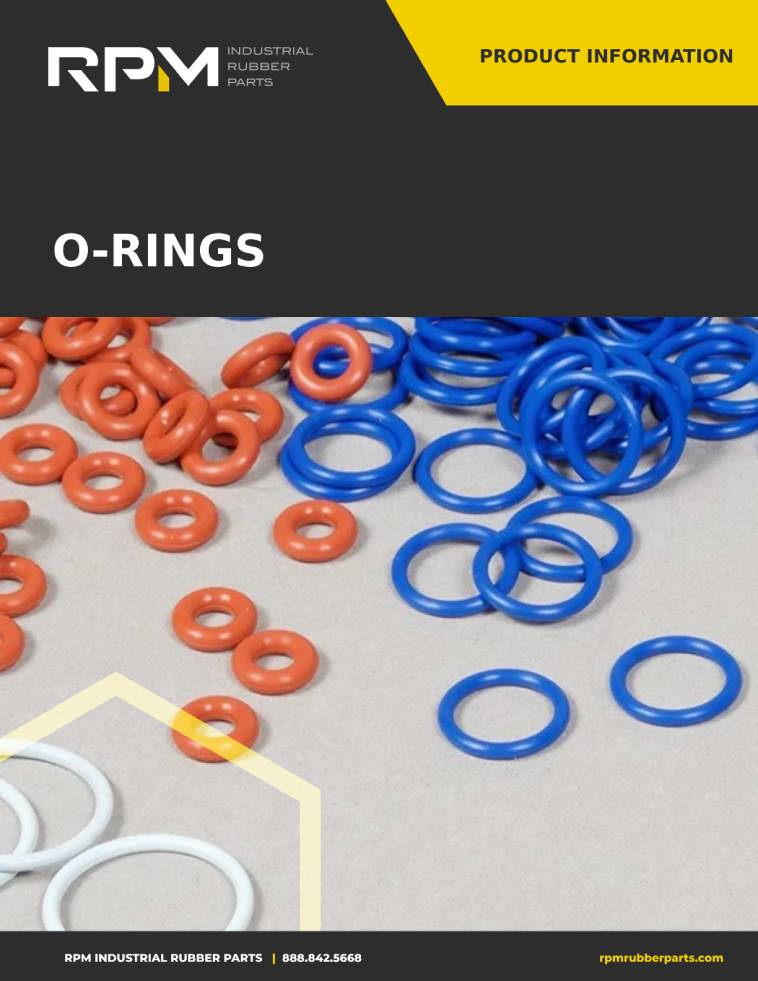

- O-Rings

Our team also offers custom molded rubber parts. With all kinds of capabilities to choose from and a variety of colors, materials and durabilities, you won’t be disappointed. Customers get to work one on one with our design and engineering team to ensure that they are getting the exact part they envisioned.

To learn more about our rubber standard and custom parts, give us a call at (888) 842-5668.

Related Resource

The Engineer’s 7-minute Guide to Rubber Molded Parts

Our free resource is a quick-reference guide to help you determine if exploring a rubber part is right for your application.